Cement

The Environmental Agenda of a Second-Term Obama Administration

Yeah, we don't know what it is either. We suspect not even Lisa Jackson knows. But of course, that doesn't keep the chattering class from speculating about what will or won't happen in the next four years on the energy and environment front. So without further ado….

Yeah, we don't know what it is either. We suspect not even Lisa Jackson knows. But of course, that doesn't keep the chattering class from speculating about what will or won't happen in the next four years on the energy and environment front. So without further ado….

Here's a pretty banal piece from the Hearst Chain that includes the premise the president is free "to approve natural gas exports and the controversial Keystone XL pipeline without fear of alienating environmentalists he needed at the ballot box."

Ah, but here's a piece from USA Today that quotes heavily from Romney supporters in industry to suggest the president will reject the pipeline and propose a slew of anti-oil and gas regulations.

Then there's this much longer and better Bloomberg piece that actually focuses on EPA rules already in the, er, pipeline, such as new lower Particulate Matter ambient air standards, the possibility of the lower ozone standard Jackson was originally going to propose before she got mugged by the White House re-election campaign, and new greenhouse gases limits for power plants.

It also mentions the possibility – brought up by industry lobbyist and Dallas native Scott Segal, no less – of a carbon tax as part of a solution to the "fiscal cliff" now getting so much post-election coverage, and talks about whether Lisa Jackson is staying or going.

Liberal thinktankers at Think Progress just posted this article advocating the "Five Essential" environmental rules that should be the focus of Obama's second term.

Finally, not mentioned in any article so far, but on the minds of kilnheads across the country, is the fate of the inane proposed revisions in cement plant emissions rules that were the subject of an August EPA national hearing at the Arlington City Hall that many of you attended. A final decision on those is due by December.

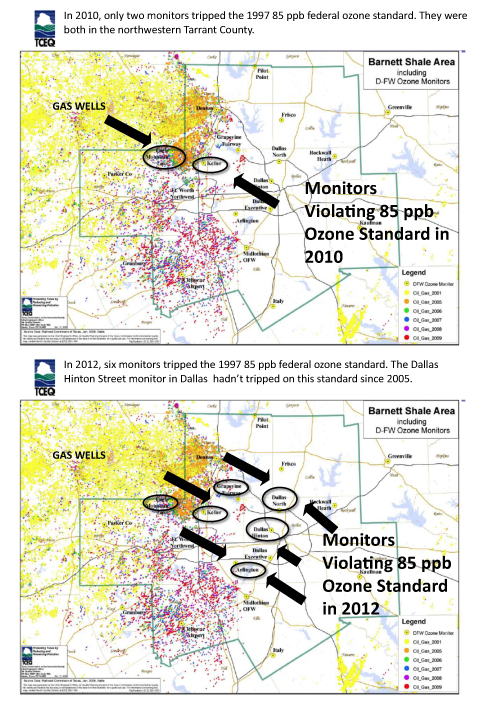

2nd TCEQ Clean Air Plan in Four Years Fails, Leaves Air Dirtier

For the second time in four years a state-designed clean air plan to bring safe and legal air to DFW residents has failed, missing its goal by an even wider margin than on its first try, and leaving local air quality worse than when it started.

For the second time in four years a state-designed clean air plan to bring safe and legal air to DFW residents has failed, missing its goal by an even wider margin than on its first try, and leaving local air quality worse than when it started.

November 1st marked the official end of the eight-month 2012 ozone season. According to the Texas Commission on Environmental Quality, or TCEQ, its plan was supposed to deliver record-breaking clean air to DFW this summer on its way to bringing the region into compliance with the Clean Air Act for the first time in two decades.

“You got your fracking fluid in my cement!” Kiln Disposal of Drilling Wastes.

It was inevitable. Like chocolate and peanut butter. Like rats and the plague.

It was inevitable. Like chocolate and peanut butter. Like rats and the plague.

Two notoriously polluting industries find solace in each other's ability to scratch each other's dirty, irritating itches.

Cement plants are always looking for ways to get paid to burn other people's garbage. It takes a lot of energy to fire a 20-foot flame at 2000 degrees 24/7 in order to cook rock. It also takes a lot of "additives". That's why cement plants started burning other companies' hazardous wastes in the 70's and 80's. Because of a loophole in federal law, 50-year old cement plants with no modern pollution controls were allowed to charge for burning highly toxic wastes from refineries and chemical plants that were otherwise supposed to be going to fully-regulated hazardous waste disposal sites.

But those official sites cost more to use, and the cement plants cost so little. That's right, cement plants charged these polluters to dispose of their wastes, but not more than the incinerators or landfills with all the bells and whistles of "regulation." In this way, cement plant operators double dip – they don't have to shell out as much for fuel they'd have to buy, and they get paid a profit to be a Dispos-All for industry. And by the way, industry calls this "recycling."

Because of the persistence of Downwinders at Risk and other citizens' groups, this loophole has been slowly but surely closing, meaning less and less hazardous waste is being burned in US cement kilns. From a peak of almost 30 kilns burning toxics in the in the 1990's, we're now down to less than a dozen. But to take the place of this lucrative lost market, cement plants across the country are turning to "non-hazardous" waste to burn. Tires, but also municipal garbage, plastic wastes, used oils, shingles, car parts and other kinds of wastes. TXI's new permit allows the burning of a dozen different kinds of industrial wastes at its huge kiln in Midlothian.

While these wastes are classified as "non-hazardous," when they come in the front gate of a kiln, it turns out they can release a lot of toxic pollution when they're incinerated. Metals like lead and cadmium and arsenic that don't burn (consult your High School physics textbook) are present. So are PCB's that have Dioxin. But burning plastic or chlorinated wastes means you can generate Dioxins even without having them present in the wastes to begin with. There's also Mercury in some of the wastes from cars that TXI and other kilns wants to burn.

So you have the release of exactly the same kinds toxic pollution you were concerned about with the burning of officially-classified hazardous wastes. But now, it's taking place "legally," – or at least it is until the law hasn't catches-up with the consequences of this kind of low-rent disposal operation. Have a waste you want to get rid of? Send it to your local neighborhood cement plant. They'll burn anything.

Enter the Natural Gas industry. They've been getting a lot of bad PR lately about their own waste problems. They have billions of gallons of what they like to call "fracking fluid," and what the rest of us would call "hazardous wastes" that's so toxic it must be disposed of in a deep underground injection well after only being used once, isolated from the rest of the earth's environment forever. But because of some well-placed loopholes, this "fracking fluid" is not considered "official" hazardous waste under federal rules. It will just unofficially injure you with its toxins.

As it turns out, injecting billions of gallons of "non-hazardous" toxic liquid under extremely high pressure near deep underground faults is a sure way to generate earthquakes. And that's what's been happening. Not only in North Texas, but other places where there are lots of injection wells. There was another small one last night in Midlothian, right down the highway from a large deep injection well near Venus. Along with the fact that most fracking fluid cannot be or is not "recycled" now and can only be used once before disposal, the fracking fluid generated by the gas industry has turned into an embarrassing sore point.

If only there was some other way the gas industry could dispose of their drilling wastes. If only they could appear to be more environmentally-friendly and save money at the same time……

And there you have the genesis of a happy marriage made in polluter heaven. I have a facility that needs stuff to burn and mix, and I'm not that particular about what the stuff has in it. You have lots of stuff that needs to be burned, er, "recycled" and you spend less when you send it to a facility like mine not specifically built to do that job. Everybody wins!

"The use of drilling wastes and muds is most preferable in cement kilns, as a cement kiln can be an attractive, less expensive alternative to a rotary kiln. In cement kilns, drilling wastes with oily components can be used in a fuel-blending program to substitute for fuel that would otherwise be needed to fire the kiln.

Cement kiln temperatures (1,400 to 1,500 degrees C) and residence times are sufficient to achieve thermal destruction of organics. Cement kilns may also have pollution control devices to minimize emissions. The ash resulting from waste combustion becomes incorporated into the cement matrix, providing aluminum, silica, clay, and other minerals typically added in the cement raw material feed stream.

Recent studies have shown that it is feasible to use such drilling waste as substitute fuel in a cement plant. The drilling mud can be processed by a centrifuge to separate remaining water, compressed by a screw into a solid pump and conveyed.

The cement companies can contribute to sustainability also by improving their own internal practices such as improving energy efficiency and implementing recycling programs. Businesses can show commitments to sustainability through voluntary adopting the concepts of social and environmental responsibilities, implementing cleaner production practices, and accepting extended responsibilities for their products."

For veterans of The Cement Wars of the 1990's this rhetoric is certainly recycled. Cement Plants are Long, Hot and Good for America! Cement plants are the best disposal devices ever. They just make everything go "poof." That's why they were built specifically to dispose of wastes of all kinds – oh wait. nope. They were built to make cement. But how great is it that they can make an entire sideline business out of dealing with, and spewing toxic chemicals into the environment?

Even though the specific article deals with the Middle East, is there any question that a cement plant in Texas or Pennsylvania, or Ohio won't try to make the case for accepting drilling wastes, if they haven't already? The permit modification TXI received to burn plastics and car wastes from the State of Texas required no public notice at all. Citizens only found out after the fact. There are only about a dozen players left in the international cement market. If they're discussing this in Egypt and Saudi Arabia, chances are they're talking about it in Zurich, Heidelberg, and Midlothian too.

Developments like this are why its important to tell the EPA it's making a big mistake to delay and change its cement plant toxic emission rules. The industry's "inputs" are changing rapidly. Two years is too long. We need the protection of those new rules now. If you haven't already clicked and sent EPA an e-mail saying you oppose this delay, the "official" comment period is over, but it couldn't hurt for the folks in DC to see your "unofficial" opposition.

It's also a lesson in why "everything is connected." Don't live near a gas well? If you live in DFW, chances are you live downwind of a kiln that could be burning the wastes of gas wells.

Italian Government Seizes Cement Plant for Toxic Violations

This is what we call enforcement.

This is what we call enforcement.

Italian Justice Department officials seized a cement kiln run by Italcementi, the world's fifth largest cement manufacturer, near the village of Velletri, southwest of Rome, for not completing updates in equipment that would bring it in line with European Union environmental standards.

It's the second time this year that the Italian government has resorted to seizure of a major polluter's facility. A steel plant was ordered shut last month.

In the case of the kiln, operations will continue while the modernization is being completed.

Italcementi owns the old Essroc cement plants in Logansport, and Speed, Indiana, Nazarath. Pennsylvania, and Martinsburg, West Virginia as well as Canada and Puerto Rico.

Midlothian Cement Plants Linked to Higher Child Asthma Rates

On the left is a computer-modeling image from the Texas Commission on Environmental Quality showing the direction of the predominant downwind plume of pollution from the three Midlothian cement plants - from extreme NW Ellis County, blowing diagnoally across Tarrant County and into Wise County. On the right is the map from the original 2009 Cook Children's Hospital CCHAPS study indicating levels of childhood asthma in the Hospital's service area. It tracks closely with the direction of the plume and asthma levels increase in closer proximity to the cemnt plants.

According to researchers Patricia Newcomb and Alaina Cyr from the UTA College of Nursing "…the bulk of Tarrant County asthma cases lie directly in the path of southeasterly winds that have historically carried high levels of particulate matter from working cement kilns in a neighboring county. Asthma prevalence increases in a linear configuration within the path of the 'cement plume' as residential location comes closer to the cement kiln area."

Exposure to Particulate Matter pollution, or soot, is a well-known known cause for asthma. It can also make a child's asthma worse.

"This latest study is one more piece of empirical evidence that we need to decrease pollution from the Midlothian cement plants to secure the right of our children to breathe without getting sick, " said Jim Schermbeck, Director of Downwinders at Risk, a local group originally founded in 1994 to oppose the burning of hazardous waste in the Midlothian cement plants.

Proximity to the pollution from the three Midlothian cement plants was the only environmental factor geographically associated with higher concentrations of childhood asthma, ruling out poverty and indoor air pollution. There also wasn't a strong correlation to urban gas drilling, although the authors concede that "urban drilling may play a part as well" in the region's higher than normal child asthma rates, and there was no direct comparison between the geography of drilling activity and area asthma levels.

In 2009, Cook Children's Hospital released its Community-wide Children's Health Assessment and Planning Survey (CCHAPS), the largest examination of childhood health in North Texas ever undertaken. It found that Tarrant County and the western side of the North Texas region suffer childhood asthma rates significantly higher than state and national averages.

In "Conditions Associated with Childhood Asthma in North Texas," published in the October edition of ISRN Allergy, Newcomb and Cyr revisit the Cook study and delve more deeply into its data. "The purpose of this study was to identify significant associations between asthma diagnosis, comorbid conditions, and social problems in children." The complete article can be accessed on the Cook Hospital CCHAPS website page devoted to asthma, under "Special Reports."

Midlothian is the home of the largest concentration of cement plant manufacturing capacity in the United States. It hosts three large cement plants – TXI , Holcim and Ash Grove – with a total of six kilns. They are the largest stationary sources of pollution in North Texas. Reports submitted by the plants themselves show they poured over a million pounds of Particulate Matter pollution into the North Texas air in 2009.

EPA recently announced that it was considering once again delaying the implementation of new federal emission rules, including stricter particulate matter pollution standards, from 2013 to 2015 that have been in the works for two decades. The delay would also water down proposed PM pollution standards. Schermbeck said Newcomb and Cyr's analysis shows the real world costs of such a rollback.

"It's a scientific fact, endorsed by EPA, that inhaling tiny bits of particulate matter can make people sick and even kill them. What this study makes clear is that the agency is senselessly condemning more Tarrant County kids to illness and suffering by delaying rules that were supposed to have been in place in the 1990's. It's time to start saving lives by reducing this kind of pollution."

Dust from Homes Near Cement Kilns Have 2 to 9 X More Dioxin

Here's some information the Midlothian Chamber of Commerce probably won't be linking to at their website.

Here's some information the Midlothian Chamber of Commerce probably won't be linking to at their website.

A national research team that includes personnel from The National Cancer Institute, Colorado Sate University, the University of Washington, and the Mayo Clinic has concluded that homes within one to three miles of cement plants contain house dust that contains 2 to 9 times more Dioxins than homes not located near kilns.

Dioxins are among the most toxic substances ever tested by EPA. Dioxin is the poison in Agent Orange. It's what made both Love Canal in New York, and Times Beach Missouri Superfund Sites. It's so toxic it's measured in grams, not pounds. It's a carcinogen and an endocrine disrupter. Like Lead and Particulate Matter, there is no known "safe" exposure level to Dioxin.

40 homes across four states were chosen from an earlier non-Hodgkin lymphoma study. Samples of dust were collected from vacuum cleaner bags and test for a variety of Dioxins (the testing for Dioxins is VERY expensive and that's one reason you don't see a lot of field tests for it). Four kinds of dioxin-emitting facilities identified by EPA were in close proximity to one or more of the sampled households – cement kilns, coal plants, sewage sludge incinerators, and medical waste incinerators. Proximity to major roadways was also considered a separate source. But "high concentrations" of Dioxins were only associated with homes near cement plants. Major roads also saw "elevated" levels, but not nearly as much as kilns.

The full study was recently published in the September edition of "Science of the Total Environment."

Midlothian currently hosts six active cement kilns. There were as many as ten up until 2008. It is the largest concentration of cement manufacturing in the nation. And all of DFW is downwind of it most of the year.

As we mentioned last week, a 1999 study by Barry Commoner and his group out of Washington University in St. Louis traced Dioxins from the TXI cement plant all the way to the Arctic Circle. So don't feel safe if you think you live far enough downwind not to be affected by the Midlothian plant plumes.

For years, Midlothian residents and others have been asking the federal government for a meaningful health effects and testing protocol for determining the total load of dioxins in and around these kilns. It hasn't come. Their requests were based on published higher incidents of certain kind of birth defects in Ellis County, as well as clusters of animal health effects observed by local ranchers and breeders. And these observations started when hazardous waste burning began in the mid-1980's. EPA has stated that waste-burning kilns release more dioxin than non-waste burning ones.

So it's important to remember that the astounding high concentrations of Dioxins that were located in homes in close proximity to a a cement kiln were linked to a kiln not burning hazardous waste. Granted, we don't know what kind of "non-hazardous wastes" it might have been burning, but the results begs the question about how much higher Dioxin levels might be in a place like Chanute, Kansas where Ash Grove's kiln is still burning hazardous wastes.

And it also once again points out why we can't be complacent about the kilns in Midlothian just because they quit burning the worst of the worst toxic wastes. Even without that practice, they pose an on-going clear and present danger to the region's public health from just their "routine" emissions. Now that all of them have or want permits to burn plastics and garbage, you could reasonably expect to see an increase in Dioxins and other forms of more exotic pollution spewing out of their tall smokestacks. And you know why their so tall don't you? So that the pollution they're releasing travels further downwind.

Another Waste Fire at a Waste Burning Cement Plant

Indian downwinders complain of air pollution from their local cement kiln

This time in India instead of Utah or South Carolina.

In Coimbatore, plastic and leather wastes stockpiled waiting to be burned as "fuel" at the Madukkarai cement works spontaneously combusted in a three hour fire that did not result in any known injuries at the plant.

However, thick columns of black smoke poured into the sky and that stuff, as the late Dr. Commoner would note, has to go somewhere. A lot of it will no doubt dind its way into the lungs of downwind residents. More than 200 tons of waste was gutted in the fire out of at total twice as large.

Despite local fire officials urging the cement plant to enclose the waste for some time, it had not done so. That is an apparent violation of state law. And readers, will it surprise you in the least to learn that the plant was already a longtime source of complaints from local residents?

Meanwhile the Fire and Rescue Services Department officials pointed out that storing combustible waste materials outside the plant without adequate protection was in violation of the Tamil Nadu fire service rule of 1990.

"It is a violation of section 250 of Tamil Nadu Fire Service Rules 1990 and we will issue a notice to the factory and will give them 15 days to store the waste materials inside a roofed structure with protective walls," said Subramanian.

Residents have been protesting against the cement factory for a long time and have submitted numerous petitions to the district administration. They claimed that the dust and smoke from the factory was causing major health complications, especially for senior citizens and children.

"We have raised the issue on numerous occasions and also submitted petitions to the district administration but till now no action has been taken," said C Palaniswamy, a resident of Kurumbapalayam.

There is a premeditated and orchestrated campaign by the cement industry to allow kilns to become garbage burners of all kinds of wastes. We've seen it manifest itself locally in Midlothian with the TXI permit that allows that plant to burn car parts and plastic wastes.

The more kilns that become gargabe burners, the more garbage of dubious content will pile up at kilns, the more often that garbage causes a fire. We've reported on three just since the summer alone. Being downind of an uncontrolled garbage fire isn't one of the talking points the industry boasts about when it's trying to sell kilns as the industrial equivalent of Kitchen disposals, but it's looking more like a standard feature rather than an option.

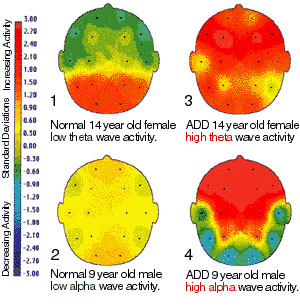

ADHD Symptoms More Likely in Children with Lead or Mercury Exposures

This in directly from Environmental Health News:

This in directly from Environmental Health News:

Children exposed to higher levels of mercury or lead are three to five times more likely to be identified by teachers as having problems associated with Attention Deficit Hyperactivity Disorder, according to a scientific study published today.

The study, of Inuit children living in Arctic Canada, is the first to find a high rate of attention-deficit symptoms in children highly exposed to mercury in the womb.

In addition, the Inuit children more often had hyperactivity symptoms if they were exposed to the same low levels of lead commonly found in young U.S. children.

Laval University scientist Gina Muckle said the findings are important because they show for the first time that the effects of mercury in children are not just subtle, but are actually noticeable to teachers. They “may be clinically significant and may interfere with learning and performance in the classroom,” the study says.

For lead, the school teachers reported much more frequent ADHD symptoms at levels far below the CDC's newly developed health guideline. Dr. Bruce Lanphear, of Simon Fraser University in Vancouver, said evidence is mounting that toxic compounds are “shifting children’s behavior...There seem to be a whole host of different toxicants that are associated with ADHD."

One of the most intriguing findings was that mercury was linked to attention deficits while lead was associated with hyperactivity. The difference may be the timing of the exposures: in the womb for mercury and during childhood for lead. The findings "suggest the brain may be sensitive to different environmental chemicals at different times in development," said Harvard epidemiologist Joe Braun.

First, there are no safe levels of lead, but teachers being able to identify ADHD behavior among kids who have levels of exposure "far below" even the new CDC recommendations is disconcerting indeed.

Second, this is why coal plant and cement plant rules to reduce Mercury and lead emissions as much as possible are a good thing and must be implemented ASAP, not delayed.

Third, none of these symptoms have ever been included in an official risk assessment of any cement plant, lead smelter, gold mine, coal plant or any other facility releasing lots of these metals into the environment. EPA regulations lag decades behind the science in terms of plugging in toxicological effects identified in the scientific literature. Over-regulated? No, not even close when you have no idea what kind of health problems your facility is causing.

Finally, the country is seeing an epidemic of ADHD. We express official dismay at this, but as far as we know, little if any attention is being paid by industry or government to try and prevent the condition through limiting exposure to toxins that can cause it, even though, "there seem to be a whole host of different toxicants that are associated with ADHD."

This is not a fatal condition. It's not a disease like cancer, or as serious as a heart attack or stroke. But does anyone doubt the challenges facing a child with moderate to severe ADHD symptoms?

This is one more consequence of pollution you never see in the paperwork, only in real life.

Imagine That: Local Regulation of Polluters

From San Francisco comes word that the area's largest Mercury polluter, the local Lehigh-Heidelberg Cement plant, may be the subject of tougher LOCAL air pollution regulations.

From San Francisco comes word that the area's largest Mercury polluter, the local Lehigh-Heidelberg Cement plant, may be the subject of tougher LOCAL air pollution regulations.

In 2011, the kiln spewed 260 pounds of Mercury into the local airshed and new regulations being proposed for the plant by the Bay Area Air Quality Management District would address not only this pollution, but emissions of dust, ammonia, dioxins, smog pollutants, and hydrocarbons.

In part, the new local rules are being spurred by EPA's own updating (and delaying) of its own air pollution rules for the nation's cement kilns. In part, local pressure from the public is driving their consideration. Bay Area for a Clean Environment collected over 1800 signatures demanding the new more stringent rules.

In California regional air boards are the prime shapers of air quality planning and policy, tailoring measures to their own geographical boundaries and problem areas. Imagine the 10-county DFW non-attainment area for smog (Collin, Dallas, Denton, Ellis, Johnson, Kaufman, Tarrant, Parker, Rockwall, Wise,) having its own air quality agency with the power to enforce new anti-pollution measures without having to get Governor Rick Perry's permission. Local control also means more opportunity for local citizens to have input rather than being blown off by ideologues in Austin intent on scoring political points rather than cleaning the air.

As we've noted before, if DFW officials really want cleaner air, they're going to have to get it themselves.

Another Chapter of Cement Kilns As Garbage Incinerators

One of the reasons it's so disheartening to have EPA rollback the deadline for new cement plant air toxics standards and gut the PM pollution provision of those standards is because of the large and fundamental shift in what's being burned is taking place within the industry. Downwinders across the country need the protection of these new rules as soon as possible, as everything, including the kitchen sink, is being thrown into kilns.

One of the reasons it's so disheartening to have EPA rollback the deadline for new cement plant air toxics standards and gut the PM pollution provision of those standards is because of the large and fundamental shift in what's being burned is taking place within the industry. Downwinders across the country need the protection of these new rules as soon as possible, as everything, including the kitchen sink, is being thrown into kilns.

There's a determined effort underway nationwide for cement plants to secure new permits or permit "amendments" or "modifications" to burn increasing amounts of municipal and industrial garbage, including lots and lots of plastics. With new regulation of hazardous waste burning in the US taking some of the fun and profit away from that practice, the trend is now headed toward burning all kinds of "solid waste" including hard to recycle bits of municipal and industrial garbage like plastics and car "fluff" – all the non-steel parts of a car or truck, including dashboard, electronics, interiors, brake linings, etc.

Locally, TXI's 2011 permit amendment – given without public notice or opportunity for comment – is the worst example of this national trend, although Holcim and Ash Grove are also burning tires, used oils, and other kinds of industrial waste already.

Now word comes of the CEMEX plant in Louisville also making plans to burn plastics and other kinds of garbage, but

"…industrial pollution has been an issue in southwest Louisville for decades. The plant is near the coal-fired Mill Creek power plant, and residents have long complained about dust and soot from both.

Denise Allgood, vice chairwoman of the Valley Village Homeowners Association, said she was not familiar with the proposal and said any change involving air pollution is likely to be sensitive.

The (pollution) that’s coming out of that place now is of great concern,” she said. “We’ve been told by the powers that be that’s it’s better than it has ever been, but I would hope that whatever (CEMEX) is considering, they are also considering the health and welfare of the people in this area.”

What could make the problem wortse? Burning plastics that release exotic new chemicals that can hitch a ride on all that old soot and dust. We're entering a whole new era of contamination by incineration once plastics-burning becomes widespread in the nation's cement kilns. That's a big reason why we need the added protection of the EPA rules.